Higher Scan Speed and Success Rates in Warehouse Inventory Barcode Scanning.

With the Viziotix barcode scanner SDK for the doks robotics and drone warehouse inventory solution.

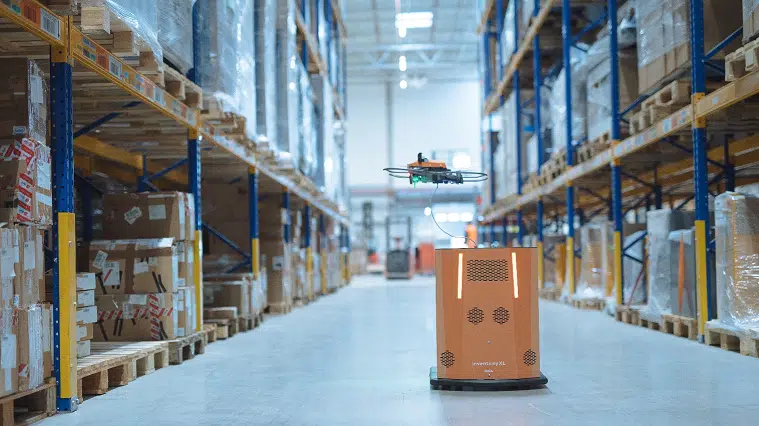

The doks. innovation “inventAIRYXL” warehouse inventory system is a robotic barcode scanning solution that scans pallets for autonomous inventory recording using cameras mounted on a drone and robotic base (AMR).

The cameras provide an image stream to the robot’s Linux-based computers to run computer-vision and barcode scanning algorithms (using a barcode scanner SDK). The data is then uploaded to the WMS (warehouse management system) to provide automated updates on inventory counts and locations. This autonomous system replaces cycle and wall-to-wall inventory counts to reduce costs and improve service levels.

Using the following metrics, doks evaluated a number of professional barcode scanner SDKs to determine which delivered the best scanning outcomes in this application:

- Read Rate (scan success rate): the percentage of pallet label successful scans per filled pallet location.

- Speed of decoding: The rate of processing the barcode images to decode the barcodes and output the data. This is a critical choke-point in maximizing the speed of the robot through the warehouse and it determines the efficiency of the inventory process.

“We chose Viziotix for our automated inventory management solution inventAIRY. Our thorough competitive analysis showed Viziotix software outperforms the other solutions available on the market today both in terms of reading rate and speed”

Mike Becker, Co-Founder and Head of Software Development, doks. innovation

The key results of this integration are:

The Problem

Prior to evaluating Viziotix, doks tested various professional barcode scanner SDKs.

These SDKs failed to find all the barcodes in the images and were slow to scan. doks therefore developed work-arounds, including preprocessing images and decoding overnight. The effective average scanning speed was 2000ms per image.

The preprocessing involved cropping and rotating images so that they would scan. Without this preprocessing, the initial scan-success rate was only 20%.

As the images were processed overnight, the WMS system was not updated until the next day, and therefore not in real time. This reduced the value of the data to end customers.

The Solution

After conducting a thorough benchmarking process, doks selected the Viziotix barcode scanner SDK to run on the robotic barcode scanning platform’s on-board Linux processor.

The Viziotix barcode scanner SDK finds every barcode in the images from the robot and drone, despite movement blur, varying illumination, and other image issues. Barcodes on the farthest edges of the photos are accurately located with Viziotix Smart-Findr. A major benefit for doks is that the solution can now scan pallet locations without the need for image pre- or post-processing. Additionally, barcodes are decoded ten times faster with the Viziotix SDK than with competing SDKs, allowing for immediate processing on the robot and real-time updates to the WMS.

The Results

With over 18,000 pallet locations in a single warehouse, any increase in read rates (scan success rates) leads to significant cost reduction and higher inventory accuracy. A 1% increase in read rate equates to 180 more pallets correctly identified and counted. It is estimated that each missing pallet requires up to 30 minutes of manual labor to find and correct the labeling issue. Lost pallets are a significant cost factor in warehouse management.

Against another market-leading professional barcode scanning SDKs, doks measured an immediate change from 20% to 95% in scan success rates on un-processed images. This rate will increase further with ongoing optimization.

doks also found that the scan time per image reduced by a factor of 10, from 2000ms to 200ms, with the Viziotix barcode SDK. As a result, real-time scanning is now possible, and the robot and its drone can now process 3800 pallets every hour. The result is instant updates to the WMS to effectively provide a digital image of the actual inventory at any given time.

The key results of this robotics barcode scanning integration are:

- The Read Rate increased from 20% to 95% on un-processed images;

- Speed of decode time per image is 10X faster;

- Real-time processing now creates a digital image of the warehouse.

For more details on this case or general information on Viziotix, please contact us: